Optimizing Industrial Gases in 3D Metal Printing

Solutions and Expertise for 3D Printing

- Optimized part treatment via proper gas selection and purity

- Uniform printing as a result of maintaining consistent conditions

- Improved control over chamber management and post-printing heat treatment

- Lower production costs via reliable and cost efficient gas supply

- Easy installation

- Increased safety

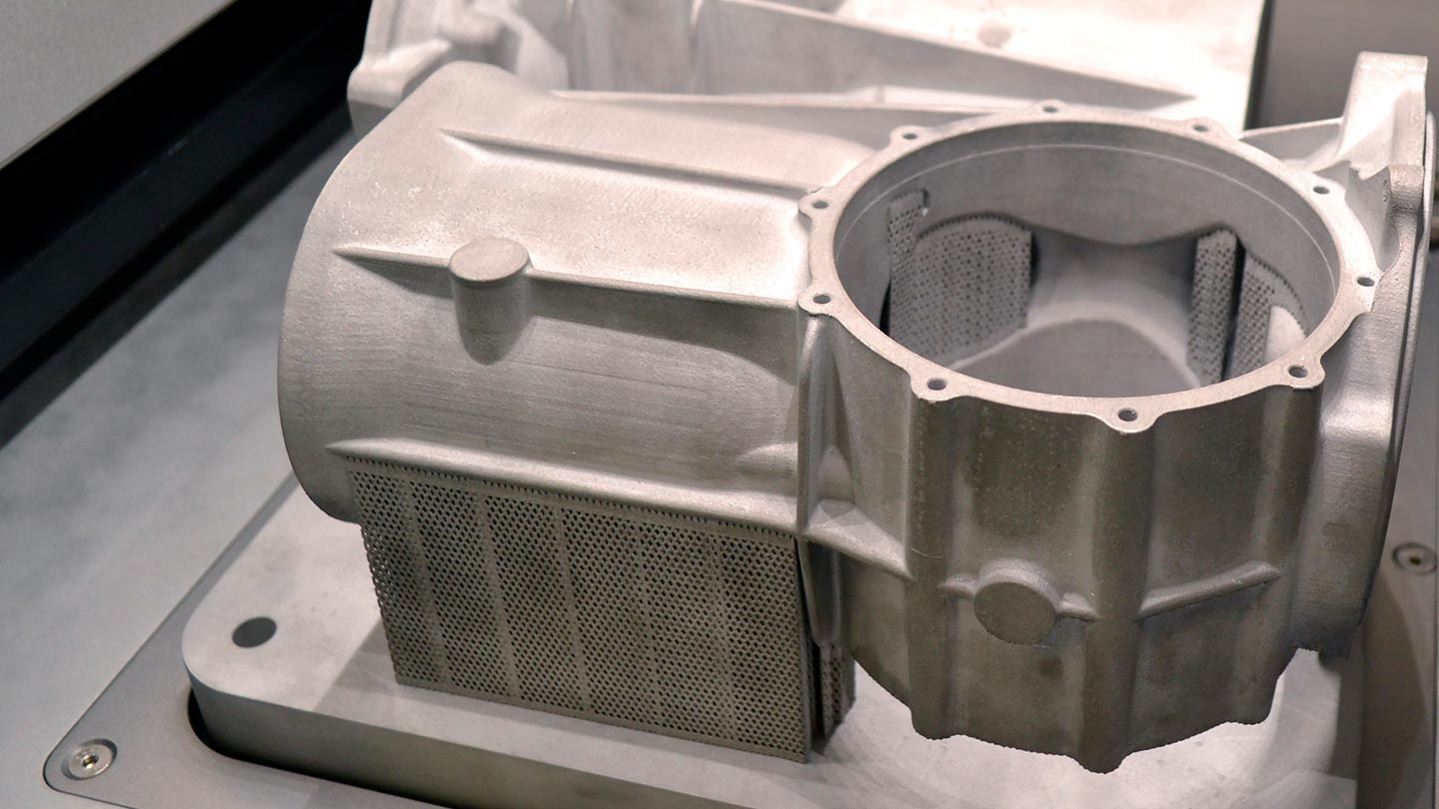

How Gases Affect the Quality of Metal Additive Manufacturing?

- Provide inert atmospheres to minimise harmful contaminants

- Allow for a narrow particle size distribution and avoids surface oxidation

- Reduce stress and improve mechanical properties, with a bright and clean surface finish

- Hot Isostatic Pressing with gases eliminates porosity and voids within the printed part

Neem contact op met onze technische experts.

Meer informatie over onze beschermgassen voor 3D-printen.

Ask the Expert

Guido Plicht

Commercial Technology Manager - Europa

Gassen

Argon

Een inert gas met unieke eigenschappen, dat wordt gebruikt in diverse industriële en analytische toepassingen. Argon wordt veel ingezet in metaalindustrie voor de productie, verwerking en fabricage van metaal.

Het kan als een zuiver gas worden ingezet voor bepaalde toepassingen voor afschermen, blanketen, uitgloeien en heet isostatisch persen (HIP) en als onderdeel van een mengsel met andere gassen, zoals kooldioxide, zuurstof, stikstof, waterstof of helium, afhankelijk van het proces en het materiaal.

Helium

Een inert gas voor cryogene toepassingen, warmteoverdracht, afscherming, lekdetectie, analyse en hijstoepassingen

Stikstof

Nuttig als gas, vanwege de inerte eigenschappen en als vloeistof voor koelen en vriezen. Vrijwel elke industrie kan profiteren van de unieke eigenschappen om de opbrengst te verbeteren, de prestaties te optimaliseren en de bedrijfsvoering veiliger te maken.